Welcome to your professional resource for mastering the basics of screen printing! Whether you’re just starting or looking to enhance your skills, this guide covers all the essential information you need. Screen printing is a popular and adaptable method for creating vivid designs on various surfaces, including fabrics and paper. In this guide, we’ll delve into how does screen printing work, its working process, necessary equipment and supplies, and effective techniques to help you achieve success. Join us on this exciting journey into the world of screen printing with Spandex, where quality meets expertise!

What is Screen Printing?

Screen printing, also referred to as silkscreen printing, is a versatile technique that involves transferring ink through a mesh screen onto a surface like fabric, paper, or plastic. The screen-printing process originated in ancient China, where it was used to craft intricate textile designs. Over time, it evolved and gained prominence across various cultures, establishing itself as a staple in the commercial printing industry by the 20th century.

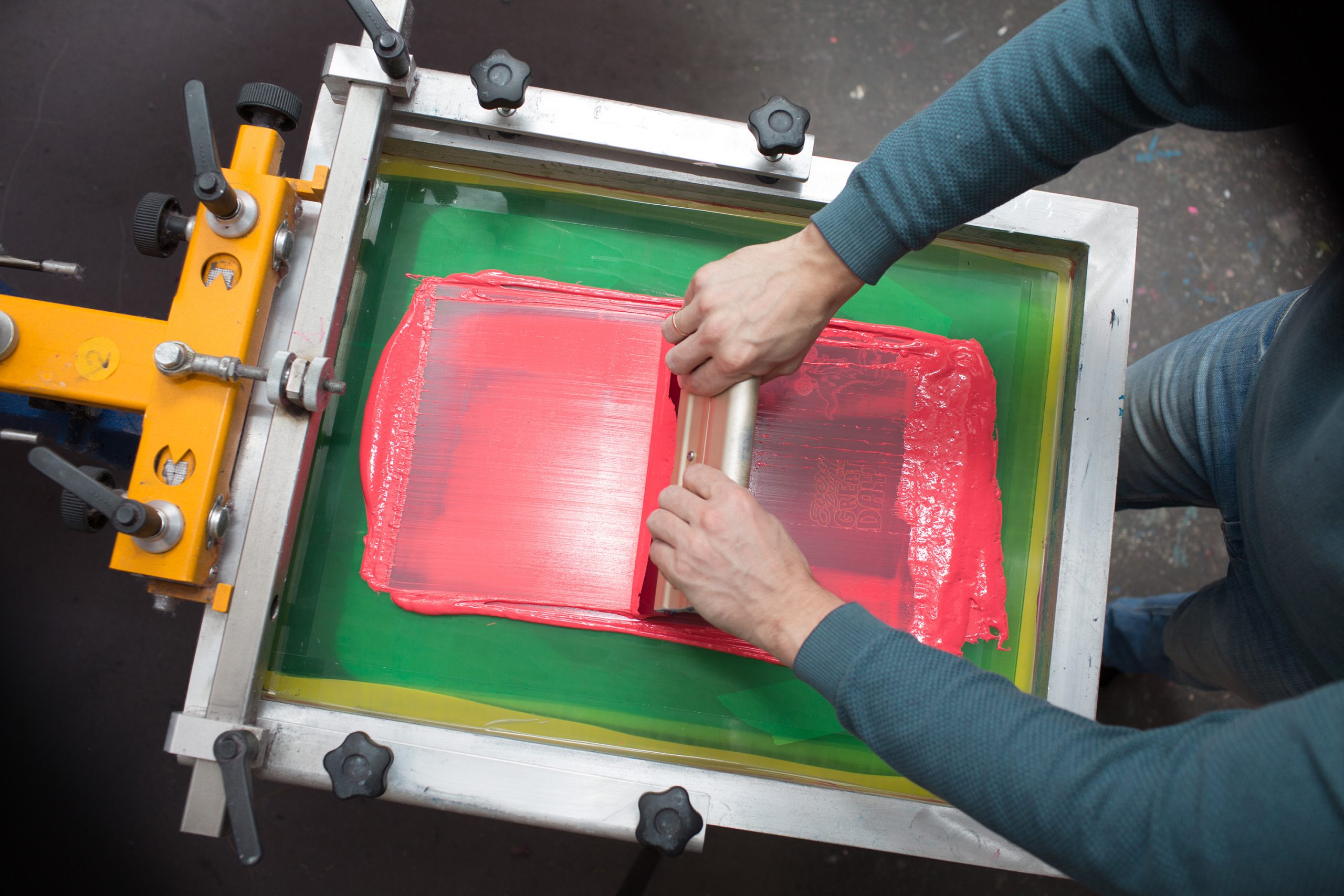

There are several screen-printing methods, each suited for specific applications. Traditional screen printing is a manual process where a stencil is placed on the screen, and ink is applied with a squeegee. This method is perfect for small runs and detailed designs. In contrast, automatic screen-printing machines can efficiently handle large quantities, making them ideal for mass production. Spandex offers industry-leading solutions for various applications.

How Does Screen Printing Work?

Understanding how screen-printing works is crucial for success in this craft. The screen-printing process starts with creating a stencil, or screen, made from fine mesh fabric stretched over a frame. This mesh allows ink to pass through specific areas while blocking others, forming the desired image or text.

Key components in the screen-printing process include the screen, ink, squeegee, and substrate. The screen transfers the design, while the ink is specially formulated to adhere to the substrate. The squeegee pushes the ink through the screen onto the substrate, ensuring an even and consistent application. The substrate is the material being printed on, ranging from T-shirts and hoodies to banners and posters. At Spandex, we provide a range of high-quality screen-printing products to help you achieve professional results in your projects. Click here to shop screen printing supplies.

Essential Equipment and Supplies

To embark on your screen-printing journey, you’ll need a variety of essential tools and materials. The basic toolkit includes screen printing presses, screens, inks, squeegees, and emulsions. Depending on your operation’s scale, you may also need exposure units, washout sinks, and heat presses. Each component plays a crucial role in ensuring high-quality prints and efficient production.

When considering screen printing presses, you have the choice between manual and automatic models. Manual presses are generally more affordable and ideal for small businesses or hobbyists, offering hands-on control and perfect for custom, low-volume orders. Conversely, automatic presses are designed for higher production rates, suitable for larger businesses, and offer speed and consistency but require a higher initial investment. Spandex offers a wide range of equipment to meet various production needs, ensuring you have access to the best tools for your screen-printing process. Click here to shop screen print equipment.

Preparing for Screen Printing

Preparing for screen printing involves crucial steps to ensure your final product meets your expectations. Begin by creating and preparing your design using graphic design software, considering the specific screen dimensions and materials for printing. Ensure your design is high-resolution and select colors compatible with your chosen inks. Once ready, print it onto a transparent film for the exposure process.

The next step in the screen-printing process is preparing the screen for printing. Select a suitable screen mesh that fits your design’s details. Clean the screen thoroughly to remove dust or grease, which can affect print quality. Apply a light-sensitive emulsion evenly across the screen. Once dried, place your printed film on the screen and expose it to UV light, creating a stencil of your design for ink transfer. It’s important to use quality materials and follow precise procedures to achieve exceptional screen print results.

Common Techniques and Tips

Achieving quality prints in screen printing requires understanding best practices that enhance design clarity and vibrancy. Start by selecting the right mesh count for your screens; finer meshes suit detailed designs, while coarser meshes are better for bold graphics. Consistent ink mixing is crucial; use a palette knife to blend inks thoroughly, ensuring even color distribution and preventing inconsistencies. Additionally, maintaining proper squeegee pressure and angle significantly impacts ink transfer onto the substrate.

Troubleshooting common screen-printing issues can save time and materials. Ink bleeding often occurs due to excessive ink on the screen or incorrect mesh selection. To resolve this, reduce the ink amount and adjust the mesh count accordingly. Misalignment of prints can usually be fixed by using registration marks and ensuring screens are properly aligned before printing. Pinholes in the print, often due to improper screen preparation, can be prevented by applying emulsion evenly and ensuring screens are adequately dried. Spandex provides expert guidance and high-quality materials to help you navigate these challenges and perfect your screen-printing process.

Contact Us

If you’re looking for top quality screen print equipment, inks, screens, squeegees and more, contact us today. Call us at 801-262-6451, write us at info.us@spandex.com or visit our website www.spandex.us.